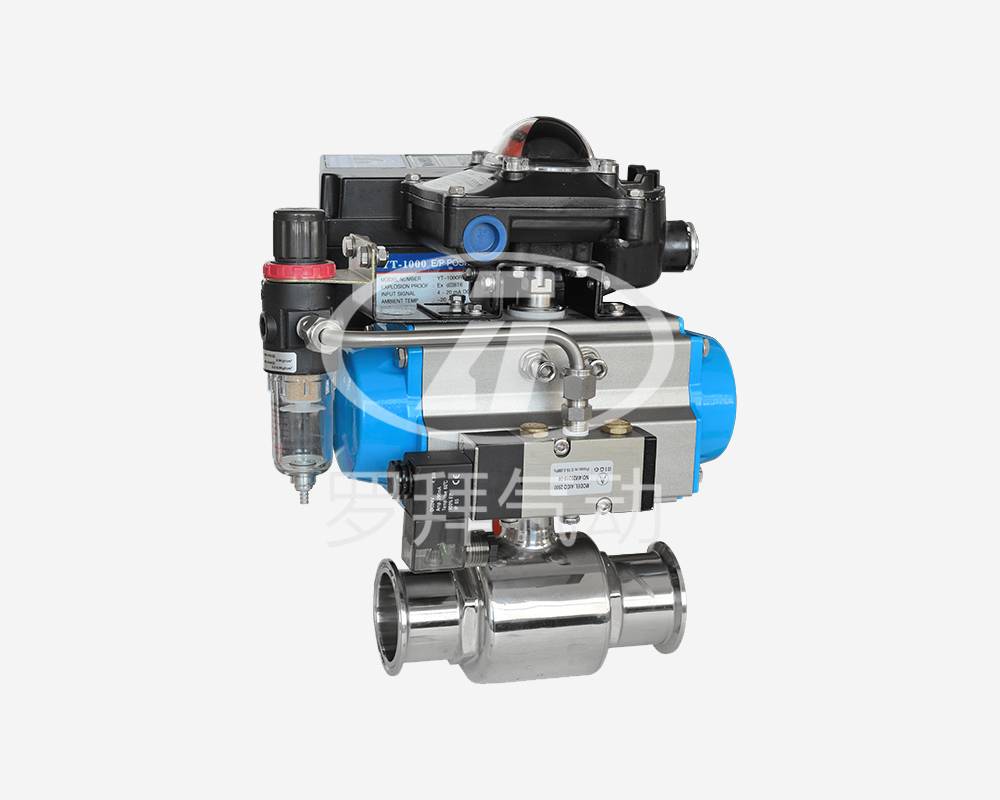

Material of pneumatic valve

Date:2017/10/27 14:09:44

Date:2017/10/27 14:09:44

1, body material should be ductile iron, and marked with the actual physical and chemical testing data of cast iron.

1, body material should be ductile iron, and marked with the actual physical and chemical testing data of cast iron.2, stem material, stainless steel stem (2CR13), large diameter valve should be embedded in stainless steel stem.

3, nut material, using cast aluminum brass or cast aluminum bronze, and hardness and strength are greater than the stem.

4, stem bushing material, its hardness and strength should not be greater than the stem, and in water immersion condition and stem, valve body does not form electrochemical corrosion.

5, sealing surface material:

There are different types of pneumatic valves, and different sealing methods and materials are required;

The common wedge gate valve, copper ring material, fixed way, grinding method should be explained;

Physical and chemical and sanitary testing data of soft sealing gate valve and rubber lining material of valve plate;

The valve should be marked on the valve body sealing surface material and the butterfly plate sealing surface material; their physical and chemical test data, especially rubber hygiene requirements, aging resistance and abrasion resistance; usually with nitrile rubber and three EPDM rubber, mixed with recycled rubber is strictly prohibited.

6. Valve shaft packing:

Because the pneumatic valve in the pipe network is usually not open and close frequently, the filling is required to be inactive for several years, and the packing is not aging, so the sealing effect is maintained for a long time;

Second, the valve shaft packing should also withstand frequent opening and closing, the sealing effect of good;

(3) in view of the above requirements, the valve shaft packing should be changed for life or not replaced for more than 10 years;

4. If the packing needs to be replaced, the design of pneumatic valve should consider the replacement of water pressure.

Transmission box

1, box material and internal and external anti-corrosion requirements consistent with the valve body principle.

2, the box should be sealed measures, box assembly can withstand 3 meters water column immersion.

3. The opening and closing limit device on the box body, the adjusting nut should be in the box or outside the box, but need special tools to operate.

4, the transmission structure design is reasonable, opening and closing can only drive the valve shaft rotation, do not make it move up and down, the transmission parts bite moderately, do not produce the load slipping when opening and closing.

5, variable transmission box and valve shaft seal can not be connected to the whole without leakage, otherwise there should be reliable anti string leakage measures.

6, there is no debris in the box, gear bite should be protected by grease.

Wenzhou Luobai Automation Co.,Ltd,

Wenzhou Luobai Automation Co.,Ltd,is one professional pneumatic actuator manufacture ,which locats in Longwan central industry Zone,Wenzhou city.Where is also named “China valve town”. More News by Wenzhou Luobai Automation Co.,Ltd,

For Immediate Service Please Call: 0577-8689-8000

CHINA

Add:No.2410 Road 2 Street 11BinHai District Longwan Zone,Wenzhou China Tel: 0577-8689-8000 8689-8555 8562-1222

Fax: 0577-8562-6588

E-mail: xtdp@luobai.org

Web: www.luobai.org,www.reedacv.com,www.reedacv.cn

Add:No.2410 Road 2 Street 11BinHai District Longwan Zone,Wenzhou China Tel: 0577-8689-8000 8689-8555 8562-1222

Fax: 0577-8562-6588

Web: www.luobai.org,www.reedacv.com,www.reedacv.cn

Copyright © 2017 Wenzhou luobai All Rights Reserved

CHINESE

CHINESE