Date:2017/4/10 8:35:04

http://en.luobai.org/content/Valve

Is one of the most common and important processing equipment,

http://en.luobai.org/content/Valve

It is an indispensable part of the whole water treatment equipment. It is a control part in the fluid conveying system. It has the functions of cut-off, regulating, diversion, preventing backflow, regulating, shunting or overflow relief. The http://en.luobai.org/content/Valve is usually composed of http://en.luobai.org/content/Valve body, http://en.luobai.org/content/Valve cover, http://en.luobai.org/content/Valve seat, opening and closing parts, drive mechanism, seal and fastener, etc. The control function is to rely on the drive mechanism or fluid to drive the opening and closing parts to lift, slide, swing or turn Movement to change the size of the flow channel to achieve.

Human use of the http://en.luobai.org/content/Valve has been nearly 4,000 years of history, and China in ancient times from the salt wells in the brine salt, had used in the bamboo pipe in the plug http://en.luobai.org/content/Valve; 1800 BC, the ancient Egyptians in order to prevent the flood of the Nile The construction of large-scale water conservancy, have also used a similar wooden cork to control the distribution of water; these are the prototype of the http://en.luobai.org/content/Valve.

Industrial http://en.luobai.org/content/Valves for a large number of applications, from the invention of the steam engine after the beginning of the beginning of the twentieth century cast steel, cast iron, forged steel and forging structure of the http://en.luobai.org/content/Valve.

http://en.luobai.org/content/Valve definition

In the water treatment industry, the http://en.luobai.org/content/Valve is a very common and important one of the processing equipment, the http://en.luobai.org/content/Valve is small, but it is an indispensable part of the entire water treatment equipment, fluid transmission system control components, with cut-off , Regulation, diversion, to prevent backflow, regulator, shunt or overflow pressure and other functions.

The http://en.luobai.org/content/Valve is usually composed of http://en.luobai.org/content/Valve body, http://en.luobai.org/content/Valve cover, http://en.luobai.org/content/Valve seat, opening and closing parts, drive mechanism, seal and fastener, etc. The control function is to rely on the drive mechanism or fluid to drive the opening and closing parts to lift, slide, swing or turn Movement to change the size of the flow channel to achieve.

http://en.luobai.org/content/Valves are widely used and are closely related to people's daily lives, such as faucets for tap water pipes and liquefied petroleum gas stoves.

Pressure reducing http://en.luobai.org/content/Valve

Are http://en.luobai.org/content/Valves. http://en.luobai.org/content/Valves are also indispensable parts for a variety of mechanical equipment such as internal combustion engines, steam engines, compressors, pumps, pneumatic drives, hydraulic drives, vehicles, ships and aircraft.

http://en.luobai.org/content/Valve classification

The http://en.luobai.org/content/Valve can be divided into two categories: automatic http://en.luobai.org/content/Valve and drive the http://en.luobai.org/content/Valve.

Automatic http://en.luobai.org/content/Valves: http://en.luobai.org/content/Valves that rely on the ability of the medium (liquid, gas) itself to act on its own. Such as

Check http://en.luobai.org/content/Valve

,

Safety http://en.luobai.org/content/Valve

,

Regulating http://en.luobai.org/content/Valve

,

Traps

,

Pressure reducing http://en.luobai.org/content/Valve

Wait.

Drive http://en.luobai.org/content/Valve: with manual, electric, hydraulic, pneumatic to manipulate the action of the http://en.luobai.org/content/Valve. Such as

gate

,

Shut-off http://en.luobai.org/content/Valve

, Throttle,

Butterfly http://en.luobai.org/content/Valve

,

Ball http://en.luobai.org/content/Valve

,

Plug the http://en.luobai.org/content/Valve

Wait.

According to the use of functions can be divided into cut-off http://en.luobai.org/content/Valve,

Regulating http://en.luobai.org/content/Valve

,

Check http://en.luobai.org/content/Valve

, Diverter http://en.luobai.org/content/Valve,

Safety http://en.luobai.org/content/Valve

, Multi-purpose http://en.luobai.org/content/Valve six categories.

(1) truncated class: also known as closed-circuit http://en.luobai.org/content/Valve, mainly used to cut off the fluid path, including

Shut-off http://en.luobai.org/content/Valve

,

gate

,

Plug the http://en.luobai.org/content/Valve

,

Ball http://en.luobai.org/content/Valve

,

Butterfly http://en.luobai.org/content/Valve

,

Diaphragm http://en.luobai.org/content/Valve

, Pinch http://en.luobai.org/content/Valve, etc .;

(2) regulating http://en.luobai.org/content/Valve: mainly used to adjust the fluid pressure, flow, etc., including the control http://en.luobai.org/content/Valve, throttle, pressure relief http://en.luobai.org/content/Valve and float control http://en.luobai.org/content/Valve;

(3) check http://en.luobai.org/content/Valve: also known as one-way http://en.luobai.org/content/Valve or check http://en.luobai.org/content/Valve, check http://en.luobai.org/content/Valve is an automatic http://en.luobai.org/content/Valve, used to prevent the reverse flow of fluid, water pump off the end of the http://en.luobai.org/content/Valve also belong to the check http://en.luobai.org/content/Valve;

(4) diverter http://en.luobai.org/content/Valve: for the distribution of fluid flow path, or two-phase fluid separation, including the slide http://en.luobai.org/content/Valve, multi-http://en.luobai.org/content/Valve,

Traps

And exhaust http://en.luobai.org/content/Valve;

(5) safety http://en.luobai.org/content/Valve: mainly used for safety protection, to prevent the boiler, pressure vessel or pipe due to overpressure and damage;

(6) multi-purpose http://en.luobai.org/content/Valve: is a more than one function of the http://en.luobai.org/content/Valve, such as cut-off check http://en.luobai.org/content/Valve can not only stop the role of the same function.

According to nominal pressure can be divided into

Vacuum http://en.luobai.org/content/Valve

, Low pressure http://en.luobai.org/content/Valve, medium pressure http://en.luobai.org/content/Valve, high pressure http://en.luobai.org/content/Valve, high pressure http://en.luobai.org/content/Valve.

(1)

Vacuum http://en.luobai.org/content/Valve

: Refers to the work pressure below the standard atmospheric pressure of the http://en.luobai.org/content/Valve.

(2) low pressure http://en.luobai.org/content/Valve: refers to the nominal pressure PN ≤ 1.6Mpa http://en.luobai.org/content/Valve.

(3) medium pressure http://en.luobai.org/content/Valve: refers to the nominal pressure PN 2.5Mpa, 4.0Mpa, 6.4Mpa the http://en.luobai.org/content/Valve.

(4) high pressure http://en.luobai.org/content/Valve: refers to the nominal pressure PN is 10.0Mpa ~ 80.0Mpa the http://en.luobai.org/content/Valve.

(5) ultra-high pressure http://en.luobai.org/content/Valve: refers to the nominal pressure PN ≥ 100.0Mpa the http://en.luobai.org/content/Valve.

According to the working temperature can be divided into ultra-low temperature http://en.luobai.org/content/Valve, low temperature http://en.luobai.org/content/Valve, room temperature http://en.luobai.org/content/Valve, temperature http://en.luobai.org/content/Valve, high temperature http://en.luobai.org/content/Valve.

(1) ultra-low temperature http://en.luobai.org/content/Valve: for the media operating temperature t <-101 ℃ http://en.luobai.org/content/Valve.

(2) low temperature http://en.luobai.org/content/Valve: for the media operating temperature -101 ℃ ≤ t ≤ -29 ℃ http://en.luobai.org/content/Valve.

(3) room temperature http://en.luobai.org/content/Valve: for the media operating temperature -29 ℃ (4) temperature http://en.luobai.org/content/Valve: for the media operating temperature 120 ℃ ≤ t ≤ 4225 ℃ http://en.luobai.org/content/Valve.

(5) high temperature http://en.luobai.org/content/Valve: for the media operating temperature t> 425 ℃ http://en.luobai.org/content/Valve.

According to the nominal diameter can be divided into small diameter http://en.luobai.org/content/Valves, small diameter http://en.luobai.org/content/Valves, large diameter http://en.luobai.org/content/Valves, large diameter http://en.luobai.org/content/Valves.

(1) small diameter http://en.luobai.org/content/Valve: nominal diameter DN ≤ 40mm http://en.luobai.org/content/Valve.

(2) in the diameter of the http://en.luobai.org/content/Valve: nominal diameter DN 50 ~ 300mm of the http://en.luobai.org/content/Valve.

(3) large diameter http://en.luobai.org/content/Valve: nominal http://en.luobai.org/content/Valve DN 350 ~ 1200mm http://en.luobai.org/content/Valve.

(4) large diameter http://en.luobai.org/content/Valve: nominal diameter DN ≥ 1400mm http://en.luobai.org/content/Valve

According to the drive classification is divided into automatic http://en.luobai.org/content/Valve type, power-driven http://en.luobai.org/content/Valve and manual http://en.luobai.org/content/Valve class.

(1) automatic http://en.luobai.org/content/Valve refers to the http://en.luobai.org/content/Valve does not require external force, but rely on the energy of the medium itself to make the http://en.luobai.org/content/Valve action. Such as safety http://en.luobai.org/content/Valve, pressure reducing http://en.luobai.org/content/Valve, trap, check http://en.luobai.org/content/Valve, automatic control http://en.luobai.org/content/Valve.

(2) power drive http://en.luobai.org/content/Valve: power drive http://en.luobai.org/content/Valve can be used to drive a variety of power sources. Divided into electric http://en.luobai.org/content/Valves, pneumatic http://en.luobai.org/content/Valves, hydraulic http://en.luobai.org/content/Valves and so on. Electric http://en.luobai.org/content/Valve: Electric driven http://en.luobai.org/content/Valve. Pneumatic http://en.luobai.org/content/Valves: http://en.luobai.org/content/Valves driven by compressed air. A http://en.luobai.org/content/Valve driven by liquid pressure such as oil. In addition there are several combinations of the above drive, such as gas - electric http://en.luobai.org/content/Valve.

(3) manual http://en.luobai.org/content/Valve: manual http://en.luobai.org/content/Valve with hand wheel, handle, lever, sprocket, by the man to manipulate the http://en.luobai.org/content/Valve action. When the http://en.luobai.org/content/Valve opening and closing torque is large, can be set between the hand wheel and stem gear or worm reducer. When necessary, you can also use the universal joint and drive shaft for long-distance operation.

Classification by structural features: The structural characteristics of the http://en.luobai.org/content/Valve are based on the direction in which the closing member moves relative to the http://en.luobai.org/content/Valve seat.

(1) cut-off: closing parts along the center of the http://en.luobai.org/content/Valve seat; such as cut-off http://en.luobai.org/content/Valve

(2) Cocks and Spheres: Closed pieces are plungers or balls, rotating around their centerline; such as plug http://en.luobai.org/content/Valves, ball http://en.luobai.org/content/Valves

(3)

Gate

Shaped: closing parts along the vertical seat center movement; such as gate http://en.luobai.org/content/Valve,

Gate

Wait

(4) swivel-shaped: closing parts around the http://en.luobai.org/content/Valve seat outside the axis of rotation; such as the swing check http://en.luobai.org/content/Valve

(5) butterfly: the closure of the disc, around the shaft inside the shaft rotation; such as butterfly http://en.luobai.org/content/Valve, butterfly check http://en.luobai.org/content/Valve

(6) Slide http://en.luobai.org/content/Valve: The closing member slides in the direction perpendicular to the channel.

According to the http://en.luobai.org/content/Valve and pipe connection can be divided into flange connection http://en.luobai.org/content/Valve, threaded connection http://en.luobai.org/content/Valve, welding connection http://en.luobai.org/content/Valve, clamp connection http://en.luobai.org/content/Valve, card sets to connect the http://en.luobai.org/content/Valve.

(1) flange connection http://en.luobai.org/content/Valve: the http://en.luobai.org/content/Valve body with a flange, and the pipeline with a flange connection http://en.luobai.org/content/Valve.

(2) threaded connection http://en.luobai.org/content/Valve: the http://en.luobai.org/content/Valve body with internal or external thread, and the pipeline with threaded connection http://en.luobai.org/content/Valve.

(3) welding connection http://en.luobai.org/content/Valve: the http://en.luobai.org/content/Valve body with a welding port, and the pipeline connected with the welding http://en.luobai.org/content/Valve.

(4) Clamp connection http://en.luobai.org/content/Valve: the http://en.luobai.org/content/Valve body with a folder, and the pipe with a clamp connected to the http://en.luobai.org/content/Valve.

(5) card sets to connect the http://en.luobai.org/content/Valve: the use of card sets and pipe connected to the http://en.luobai.org/content/Valve.

Classification of non-metallic materials by http://en.luobai.org/content/Valve material, metal material http://en.luobai.org/content/Valves, metal body lining http://en.luobai.org/content/Valves.

(1) non-metallic materials http://en.luobai.org/content/Valves: such as ceramic http://en.luobai.org/content/Valves, glass steel http://en.luobai.org/content/Valves, plastic http://en.luobai.org/content/Valves.

(2) metal materials http://en.luobai.org/content/Valves: such as copper alloy http://en.luobai.org/content/Valves, aluminum alloy http://en.luobai.org/content/Valves, lead alloy http://en.luobai.org/content/Valves, titanium alloy http://en.luobai.org/content/Valves, Monel alloy http://en.luobai.org/content/Valves cast iron http://en.luobai.org/content/Valves, carbon steel http://en.luobai.org/content/Valves, cast steel http://en.luobai.org/content/Valves, low alloy steel http://en.luobai.org/content/Valves, high alloy steel http://en.luobai.org/content/Valves.

(3) metal body lining http://en.luobai.org/content/Valve: the http://en.luobai.org/content/Valve body shape for the metal, the internal contact with the main surface of the media are lining, such as lining the lead http://en.luobai.org/content/Valve, lined with plastic http://en.luobai.org/content/Valves, lining enamel http://en.luobai.org/content/Valve.

According to the direction of the switch can be classified as:

(1) angular travel including ball http://en.luobai.org/content/Valve, butterfly http://en.luobai.org/content/Valve, plug http://en.luobai.org/content/Valve and other classification;

(2) straight stroke, including gate http://en.luobai.org/content/Valve, globe http://en.luobai.org/content/Valve, angle seat http://en.luobai.org/content/Valve;

General classification method

This classification method is not only the principle, the role and structure by division, is the international and domestic most commonly used classification method. General sub-gate http://en.luobai.org/content/Valve, globe http://en.luobai.org/content/Valve, throttle http://en.luobai.org/content/Valve,

Instrument http://en.luobai.org/content/Valve

, Plunger http://en.luobai.org/content/Valve,

Diaphragm http://en.luobai.org/content/Valve

, Plug http://en.luobai.org/content/Valve, ball http://en.luobai.org/content/Valve, butterfly http://en.luobai.org/content/Valve, check http://en.luobai.org/content/Valve, relief http://en.luobai.org/content/Valve safety http://en.luobai.org/content/Valve, trap, regulating http://en.luobai.org/content/Valve, bottom http://en.luobai.org/content/Valve, filter, sewage http://en.luobai.org/content/Valve.

The http://en.luobai.org/content/Valves may be named individually or in combination according to various classification methods, or may be named according to the structural features or specific uses of the opening and closing parts.

The basic parameters of the http://en.luobai.org/content/Valve are working pressure, operating temperature and caliber. For a large number of http://en.luobai.org/content/Valves used in industrial pipelines, commonly used nominal pressure and nominal diameter as the basic parameters. Nominal pressure refers to a material of the http://en.luobai.org/content/Valve, at the specified temperature, the maximum allowable working pressure. Nominal diameter refers to the nominal diameter of the http://en.luobai.org/content/Valve body and the joint end of the pipe.

http://en.luobai.org/content/Valve according to its type and use have different requirements, mainly sealed, strength, regulation, circulation, opening and closing performance. In the design and selection of http://en.luobai.org/content/Valves, in addition to taking into account the basic parameters and performance, but also consider the performance of the fluid, including the fluid phase (gas, liquid or solid particles), corrosive, viscosity, toxicity, flammable and explosive , Preciousness and radioactivity. (According to China's first http://en.luobai.org/content/Valve network)

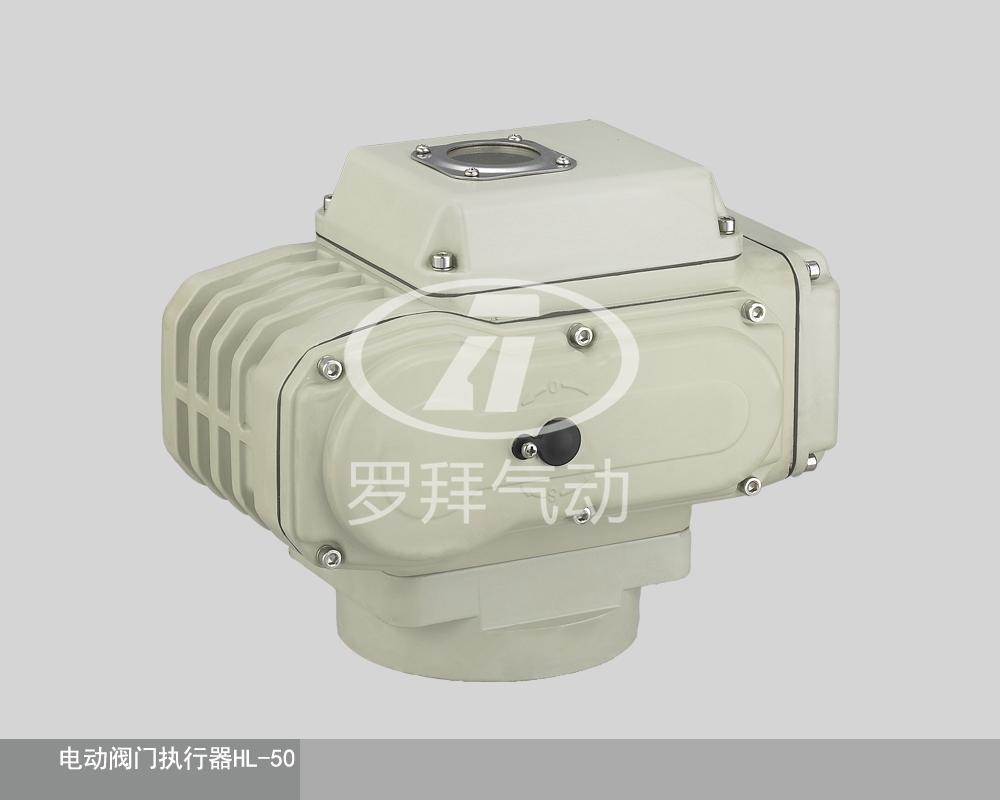

Wenzhou Luobai Automation Co.,Ltd,

Wenzhou Luobai Automation Co.,Ltd,is one professional pneumatic actuator manufacture ,which locats in Longwan central industry Zone,Wenzhou city.Where is also named “China http://en.luobai.org/content/Valve town”. More News by Wenzhou Luobai Automation Co.,Ltd,Add:No.2410 Road 2 Street 11BinHai District Longwan Zone,Wenzhou China Tel: 0577-8689-8000 8689-8555 8562-1222

Fax: 0577-8562-6588

Web: www.luobai.org,www.reedacv.com,www.reedacv.cn

CHINESE

CHINESE